Elastic Modulus Of Kraft Paper

Modulus of elasticity strongly decreased in the range of 20 53 compared to standard conditions for all the paper grammages. Vainio A Paulapuro H 2007 In kraft pulp the elastic modulus starts to increase significantly at 50 solids content.

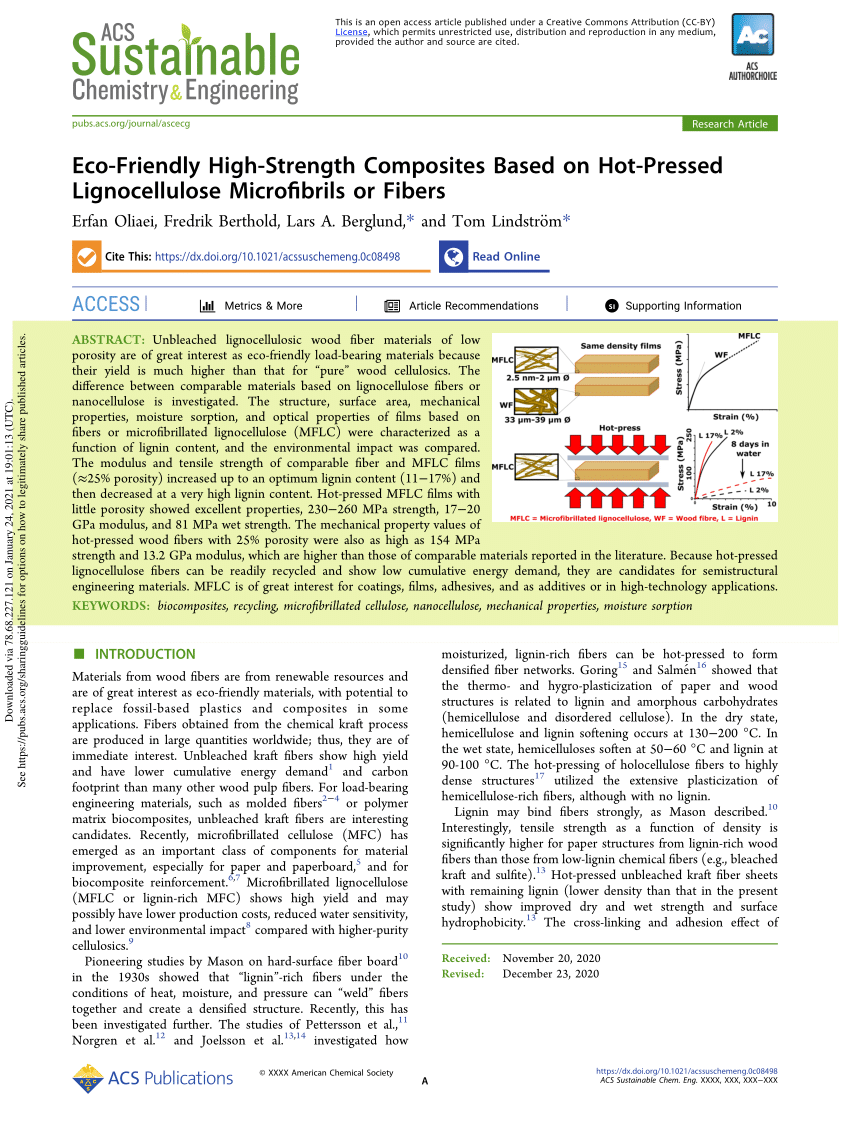

Master Curve Of The Reduced Elastic Modulus For A Kraft Sack Paper The Download Scientific Diagram

The starting point for such analysis is the theory of Cox 3.

Elastic modulus of kraft paper. Introduction The modulus of elasticity of pile material E is an important parameter for the interpretation of both static and dynamic load tests on piles. The bulk modulus also known as the volume modulus of elasticity. A stiffer material will have a higher elastic modulus.

Elastic modulus is used to characterize biological. Oth-erwise the fibers would disintegrate into the solution. The elastic modulus allows you to determine how a given material will respond to Stress.

During the pressing of the paper web in the press section of the paper machine the dry solids content is increased from about 20 to 40-55. Bending tests The specimens of the 3-points bending tests do not require any particular preparation. By further approach it was found that cube of elastic modulus is in linear proportion to square of tensile strength of paper.

If it is higher than the loss modulus the material can be regarded as mainly elastic ie. The change in the modulus must happen because of bond formation since wet fibers have higher rigidity than wet bonds otherwise the fibers would disintegrate into the solution. V H12 and v H21 are the Poissons ratios of the core in plane 12 and 21 respectively.

GE21ν where is Poissons ν ratio. A review has been made of the previous attempts to formulate a theory for the elastic modulus of paper in terms of fibre properties. The fibers tested in this project are wood fibers.

The energy is stored elastically or dissipated. The Storage or elastic modulus G and the Loss or viscous modulus G The storage modulus gives information about the amount of structure present in a material. The zero-span strength was evaluated on handsheets produced from the pulps without preceding straightening of the fibres.

This is due to the hypothesis of this paper that the properties in the compression direction are. The modulus of elasticity of steel is 200 GPa 29000000 psi. Mechanical deformation puts energy into a material.

The biaxial theory is developed and the elastic modulus is written in terms of the moduli of the fibres and the bonded area of the sheet. Paper can consist of nonwood fibers as well as wood fibers. Regression equations relating the stiffness of the sandwich panels to the shelling ratio and core cell size were obtained using the finite element model simulated results and were found to compare well with the existing models for layered wood composites.

Nonwood fibers originate from natural sources such as food crop residues and cotton. Their dimensions are 200 x 60 x 401 mm. Burst Factor Bursting Strength gcm 2 Grammage gm 2 or.

The modulus of elasticity was observed to be higher in the machine direction MD than other directions for all the paper grammages. You can use the elastic modulus to calculate how much a material will stretch and also how much potential energy will be stored. Burst Index Bursting Strength kPa Grammage gm 2 or.

Therefore the focus will be on the properties of those fibers. It can be calculated from the elastic modulus by the following formula. GRADES OF WASTE PAPER.

G MDCD MPa is the shear elasticity modulus of paper. The biaxial modulus has been measured for three levels of fibre bonded area for one pulp and these admittedly sparse data are in agreement with the theory. An elastic modulus has the form.

Cell size only affected the modulus of elasticity of the sandwich panels under the flat-wise compression and panels inter-laminar shear modulus. MODULUS OF ELASTICITY The modulus of elasticity Youngs modulus E is a material property that describes its stiffness and is therefore one of the most important properties of solid materials. TYPICAL DENSITY AND BULK OF SOME PAPERS.

The material model is assumed to be elastic and homogeneous with a uniform modulus of elasticity E. E MD MPa is the linear elasticity modulus of paper. Fillers have an important role in paper and are used because of their brightness and fine.

Wet fibers have higher ri-gidity than wet bonds so the modulus must changes because of bond formation. He initially assumed that the strain in a sheet of paper is uniform so that the stress in each fiber may be calculated from the stress transformation equation Timoshenko and Goodier 32. Ensure the use of a realistic elastic modulus value and hence the correct interpretation of the distribution between the shaft and end resistances.

Where E H1 MPa and E H2 MPa are the linear elasticity modulus MPa of the cellular panel core in directions 1 and 2. Chapter 15 Modulus of Elasticity page 79 15. Start of bonding can be derived from the elasti c modulus of paper duri ng drying.

δ def stress strain displaystyle delta stackrel text. Be measured by the elastic modulus of paper during drying. While the elastic modulus is the relationship between normal axial stress and strain the torsional modulus is the relationship of shear stress and shear strain.

Bursting strength depends on basis weight of paper. Elastic phase before reaching the failure as the detachment of flutings Fig. The controlling mechanisms for the elastic modulus of paper have been examined by Page et al.

By understanding the modulus of elasticity of steel we can claim that steel is more rigid than wood or polystyrene as it has a tendency to experience deformation under an applied load. 32 Fibre network build-up. The suggestion is made that by considering the case of uniaxial stress previous authors have attempted a problem that.

This value of modulus of elasticity of steel indicates that steel has a high bearing limit and. It may be written as E 3 α TS 2 or TSα 2 E 3. It represents the energy stored in the elastic structure of the sample.

The phase shift is. Investigation of elastic moduli of Kraft paper honeycomb core sandwich panels Zheng Chen Ning Yan Faculty of Forestry University of Toronto 33 Willcocks Street Toronto Ont Canada M5S 3B3. L x mm and S y mm are.

MOE in z direction E cz thickness direction of the honeycomb core and shear modulus of the Kraft paper honeycomb core were obtained by the developed FE model according to the criteria that the stiffness of the honeycomb core in directions x y and z E x E y E z shear modulus of the core under edgewise loading G xy and shear modulus of the core under the inter-laminar shear loading along. To normalized the bursting strength for various paper bursting strength is reported as. The elastic modulus of an object is defined as the slope of its stressstrain curve in the elastic deformation region.

The span value is 160 mm giving the span-to-thickness ratio Lh equal to 39 minimizing therefore the shearing effect. G H12 MPa is the shear elasticity modulus of the core in plane 12.

Effect On Paper Properties By Increasing The Grammage Range 15 60 Download Table

Master Curve Of The Reduced Elastic Modulus For A Kraft Sack Paper The Download Scientific Diagram

Master Curve Of The Reduced Elastic Modulus For A Kraft Sack Paper The Download Scientific Diagram

Posting Komentar untuk "Elastic Modulus Of Kraft Paper"